#RPET

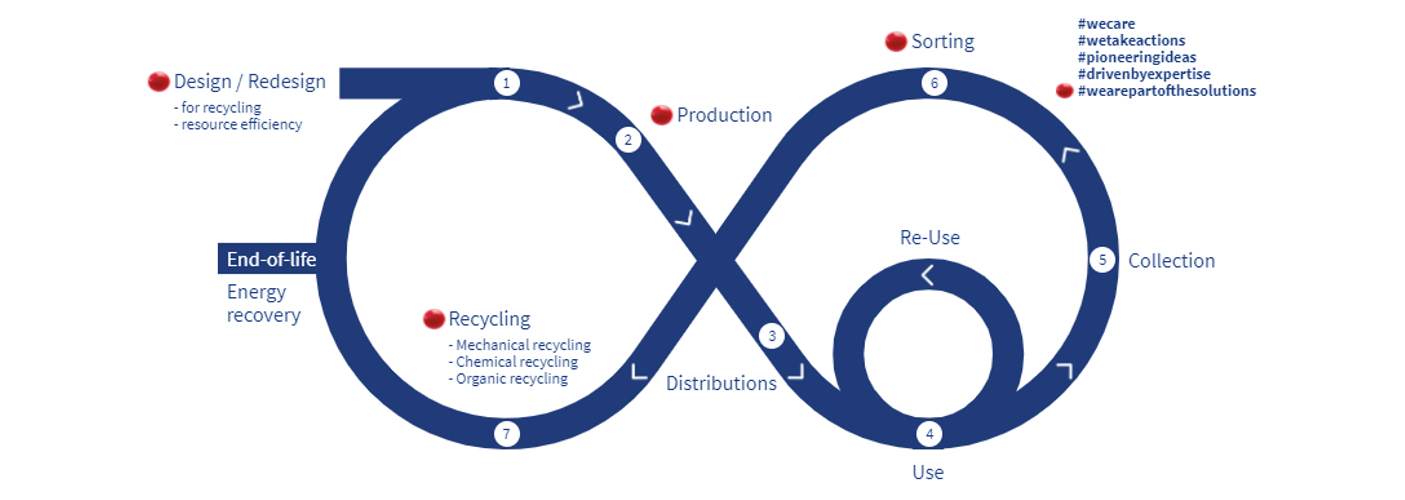

The traditional “take, make and dispose” extractive industrial model is being replaced with the concept of a restorative and regenerative circular economy.

PET, the most widely recycled plastic in the world, is at the forefront of this move to sustainability. Its properties allow for superior innovation, both in terms of package design and performance, allowing manufacturers to meet customer needs for new and sophisticated product profiles with shelf-popping options.

Besides separate collection and proper sorting of various PET packaging products, design for recycling is a major tool that can help boost their circularity.

At Sukano, we remain at the forefront of this journey. It is aligned with the core pillars that have defined the success of the company over the past 30 years: pioneering ideas combined with technical expertise.

The company launches a global campaign to lead the #wearepartofthesolution platform to deliver improved social standards demanded by consumers and society via proven scientific performance and technology.

#RPET

SUKANO Melt Enhancer Masterbatches allows you to upcycle instead of just recycle.

This masterbatch ensures uniform cell structure, improving mechanical performance and processing stability enabling the use of recycled PET in bottles or trays packaging.

Since different end applications require different product performances – and processing technology is not uniform at every industrial center – our specialists can help develop the most accurate and appropriate reactive chemistry to allow you enjoy the greatest value over benefit ratio.

SUKANO Impact Modifier Masterbatches enable producers to include a higher dosage of RPET in the core layer of the end application, while maintaining(or even improving) the cost base and film performance.

Pioneered SUKANO Slip/Antiblock Masterbatches for PET reduces the coefficient of friction(COF) of films and cut sheets.

This allows deep drawn applications to demold and denest much more easily, films have less tendency to stick during winding an unwinding, and thermoformed parts are destacked without surface abrasion.

Beyond that, the masterbatch helps improve processing, printability and transparency.

SUKANO NIR-detectable Black and other Colorsmay not have visible light, but they are definitely detectable.

In fact, black and other colors can be detected through classification equipment and must be detected. Strictly adhering to EPBP (European PET bottle platform–https://www.epbp.org/) design guidelines, Sukano successfully submitted the Black Master Placement portfolio to French classification mechanical technology leaders to certify its portfolio for detection.

We're happy to share the results with you. Please contact Sukano for all necessary details.

SUKANO Combi Masterbatches – Imagine a world where is an only single type of plastic exists and can be mixed together for future plastic product manufacturing. This is actually feasible today.

Sukano can support #designforrecyclability with #wearepartofthesolution.

If any polymer is being wasted or has not been ideally used up, please let us know and we will provide you with a technical proposal to reuse to avoid leakage from the plastic industry value chain.

This masterbatch ensures uniform cell structure, improving mechanical performance and processing stability enabling the use of recycled PET in bottles or trays packaging.

Since different end applications require different product performances – and processing technology is not uniform at every industrial center – our specialists can help develop the most accurate and appropriate reactive chemistry to allow you enjoy the greatest value over benefit ratio.

SUKANO Impact Modifier Masterbatches enable producers to include a higher dosage of RPET in the core layer of the end application, while maintaining(or even improving) the cost base and film performance.

Pioneered SUKANO Slip/Antiblock Masterbatches for PET reduces the coefficient of friction(COF) of films and cut sheets.

This allows deep drawn applications to demold and denest much more easily, films have less tendency to stick during winding an unwinding, and thermoformed parts are destacked without surface abrasion.

Beyond that, the masterbatch helps improve processing, printability and transparency.

SUKANO NIR-detectable Black and other Colorsmay not have visible light, but they are definitely detectable.

In fact, black and other colors can be detected through classification equipment and must be detected. Strictly adhering to EPBP (European PET bottle platform–https://www.epbp.org/) design guidelines, Sukano successfully submitted the Black Master Placement portfolio to French classification mechanical technology leaders to certify its portfolio for detection.

We're happy to share the results with you. Please contact Sukano for all necessary details.

SUKANO Combi Masterbatches – Imagine a world where is an only single type of plastic exists and can be mixed together for future plastic product manufacturing. This is actually feasible today.

Sukano can support #designforrecyclability with #wearepartofthesolution.

If any polymer is being wasted or has not been ideally used up, please let us know and we will provide you with a technical proposal to reuse to avoid leakage from the plastic industry value chain.