PRODUCTS

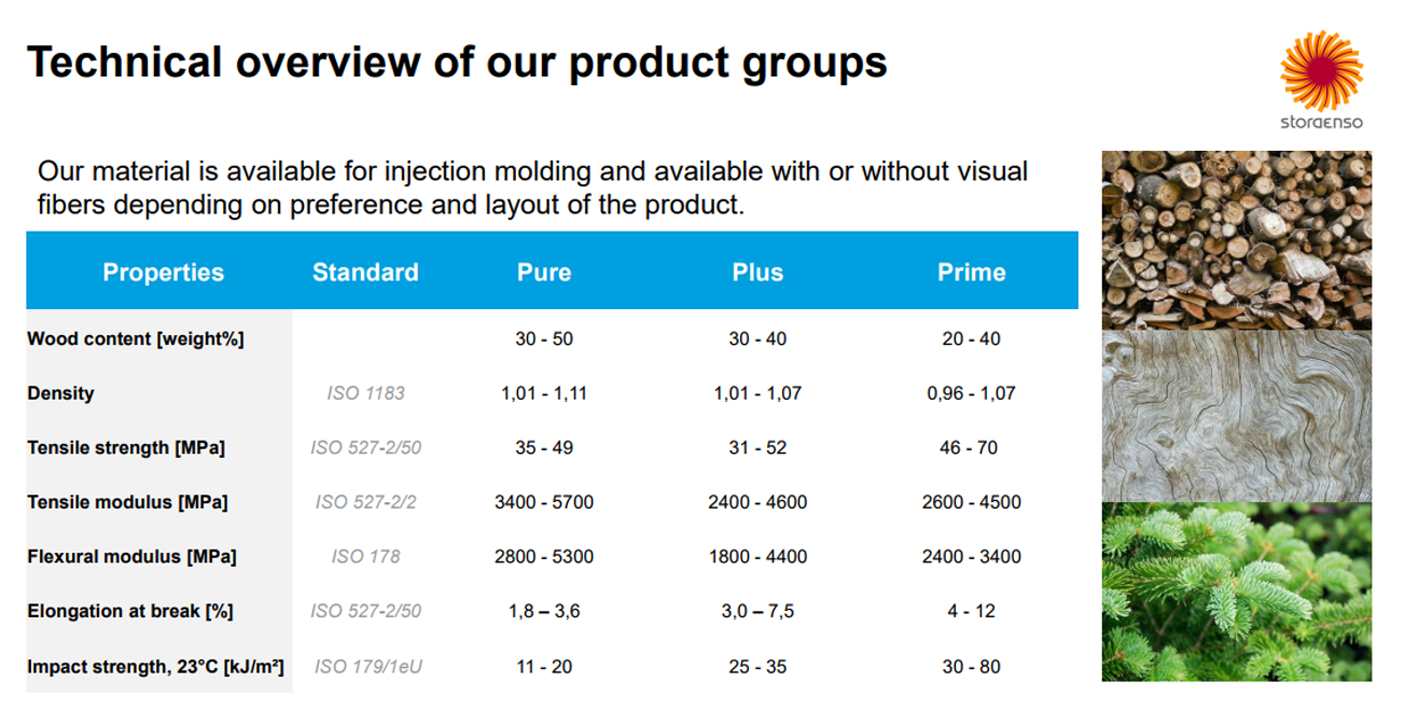

- 8 standard grades for injection moulding.

- Available with or without visual fibres

- Most grades food contact approved.

- Can be used as a masterbatch in combination with e.g. PP, for thin-walled products or products requiring impact strength above 25-27 kJ/m2

- Competitively priced with ability to compete with common basic plastics.

- 30-50% wood fibres and virgin polymer.

- Suitable for products with basic demands and thicker walls.

- Masterbatch option exists.

- Pure grades generates a minimum of 51% emission savings compared to PP.

- Food containers

- Kitchen utensils and plates

- Furniture

- Industrial components

- Toys

- 30-40% wood fibres and virgin polymer

- Grades for injection moulding.

- Softer materials compared to Pure, which provides better plasticity, impact strength and elongation at break.

- For products requiring impact strength and formability.

- 3 standard grades for Partially food contact approved

- Available with or without visible fibres

- Tailor-made solutions available.

- Kitchen utensils

- Toys

- Furniture

- Automotive

- Retail & Logistics

- 30-50% wood fibres and virgin polymers

- Grades for injection moulding.

- urable material with both excellent impact and tensile strength.

- Ability to replace plastics such as PPGF and PA

- Available with or without visual fibres

- 2 standard grades for injection moulding

- Great options for custom made grades based on your demands

- Industrial components

- Automotive

- Safety products

- Technical products

- Casing & components